Design and Structure

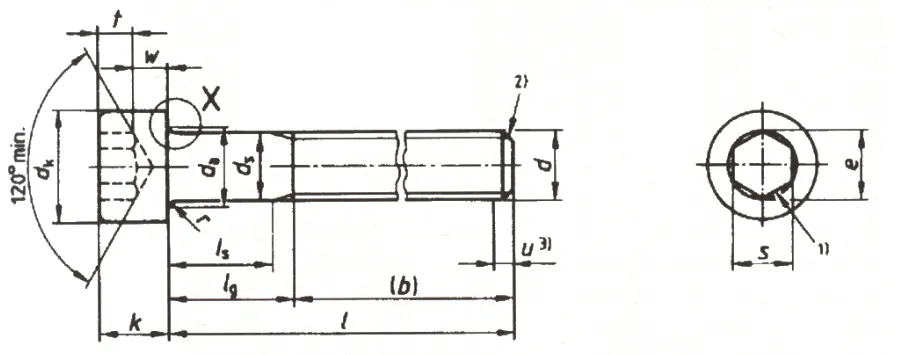

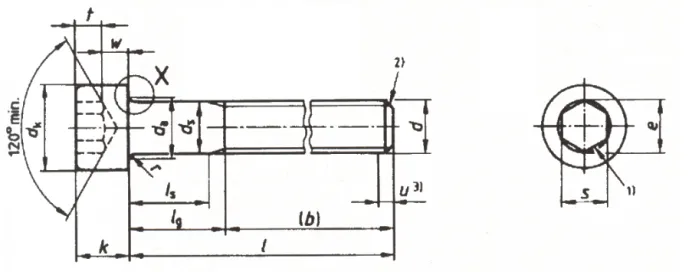

The most distinctive feature of the Hex Socket Head Cap Screw is its cylindrical head, which provides a smooth and unobtrusive appearance. Unlike traditional bolts with external hexagonal or Phillips heads, Allen bolts are designed to sit flush or slightly recessed, making them ideal for applications where space is limited or where a clean, streamlined look is desired. The absence of protruding edges reduces the risk of snagging or interference with surrounding components, ensuring safer and more efficient operation in machinery and equipment.

At the center of the head is a precisely machined hexagonal socket, engineered to accommodate an Allen wrench (hex key) or a compatible power tool attachment. This internal drive design offers several advantages over conventional fasteners. First, it allows for higher torque application without the risk of cam-out (slippage), which is common with Phillips or slotted screws. Second, the recessed hex socket minimizes wear on the tool and the fastener, extending the lifespan of both. The tight fit between the wrench and the socket ensures a secure grip, reducing the likelihood of stripping the drive and making installation and removal more efficient.

Material and Strength

Hex Socket Bolt are typically manufactured from high-strength steel, ensuring exceptional durability and load-bearing capacity. The material selection is critical, as these fasteners are often subjected to high-stress environments where shear and tensile strength are paramount. Depending on the application, they may also be made from stainless steel, alloy steel, or titanium, each offering distinct advantages in terms of corrosion resistance, weight, and mechanical properties.

The high-grade steel used in these bolts undergoes rigorous heat treatment processes to enhance hardness and tensile strength. This ensures that the screws can withstand substantial torque without deformation or failure. The threading is precisely cut to provide optimal engagement with mating nuts or threaded holes, distributing the load evenly and preventing premature wear. For applications requiring extreme strength, such as in automotive, aerospace, or heavy machinery, socket head cap screws are often rated according to industry standards (e.g., ISO 4762, DIN 912, or ASTM A574), guaranteeing consistent performance under demanding conditions.

Corrosion Resistance and Surface Treatment

To ensure long-term performance in harsh environments, Hex Socket Bolt are often treated with advanced coatings that enhance corrosion resistance. Common surface treatments include zinc plating, black oxide, and hot-dip galvanizing, each providing a protective barrier against moisture, chemicals, and oxidation.

Zinc Plating: A widely used electroplating process that deposits a thin layer of zinc on the screw’s surface, offering moderate corrosion resistance while maintaining a bright, metallic finish.

Black Oxide: This treatment creates a blackened surface that improves wear resistance and reduces light reflection, making it suitable for applications where low visibility is preferred.

Hot-Dip Galvanizing: A thicker zinc coating applied through immersion in molten zinc, providing superior protection in outdoor or marine environments.

For applications requiring maximum corrosion resistance, stainless steel (e.g., 304 or 316 grade) or titanium screws are preferred, as they naturally resist rust and chemical degradation without additional coatings.

Versatility and Applications

Hex Socket Bolt are utilized across a broad spectrum of industries due to their adaptability and performance. Some key applications include:

Machinery and Equipment: Their high strength and precise torque capabilities make them ideal for securing critical components in industrial machinery, CNC equipment, and automation systems.

Automotive and Aerospace: Used in engine assemblies, chassis components, and aircraft structures where reliability under vibration and extreme forces is essential.

Electronics and Consumer Goods: The low-profile design is advantageous in compact devices, ensuring secure fastening without protruding hardware.

Construction and Infrastructure: Employed in structural connections where durability and resistance to environmental factors are necessary.