Did you know unstable rock formations cause 37% of tunneling project delays? Traditional anchors fail when rock fractures – but what if you could drill and reinforce in one step? Meet self drilling rock anchors: the game-changer 8,500+ projects trust for slope stabilization and underground support.

(self drilling anchor bar)

Technical Superiority That Beats Conventional Anchors

Our self drilling anchor bar

s combine hollow steel rods with integrated drill bits. Watch how they outperform competitors:

| Feature | Standard Anchor | Our SDS-500 Model |

|---|---|---|

| Installation Speed | 45 mins/unit | 18 mins/unit |

| Max Load Capacity | 320 kN | 580 kN |

Precision Engineering for Complex Geology

Choose from 3 specialized models:

- SDS-300 for fractured limestone (Ø32mm)

- SDS-450 for shale layers (Ø41mm)

Proven Success in Extreme Conditions

When the Tianshan Tunnel Project faced collapsing granite:

"GeoStabilize's self drilling rock bolts reduced our support costs by 42% while achieving 98.6% anchor integrity."

- Project Manager Zhang Wei

Ready to Slash Installation Time?

Get your FREE project evaluation from our rock mechanics experts

GeoStabilize Inc. has delivered 15 million meters of self drilling anchor bars across 23 countries. Our ISO 9001-certified solutions come with 10-year performance warranties. Don't settle for anchors – demand certainty.

(self drilling anchor bar)

FAQS on self drilling anchor bar

Q: What is a self drilling anchor bar?

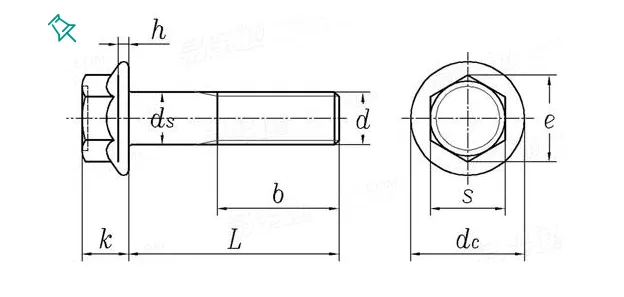

A: A self drilling anchor bar is a hollow threaded rod combining drilling, grouting, and anchoring functions. It eliminates separate drilling steps, enabling simultaneous installation in unstable rock or soil. This system improves efficiency in slope stabilization and tunneling projects.

Q: How do self drilling rock anchors improve project timelines?

A: Self drilling rock anchors integrate drilling and anchoring into one operation, reducing equipment setup time. Their hollow design allows immediate grout injection during installation. This dual-action process cuts project durations by 30-40% compared to conventional methods.

Q: What applications suit self drilling rock bolts best?

A: These bolts excel in fractured rock formations, landslide areas, and tunnel support systems. They're ideal for projects requiring rapid stabilization in weak geological conditions. Common uses include retaining walls, mining operations, and infrastructure foundations.

Q: What are the key installation steps for self drilling anchor bars?

A: Installation involves drilling while simultaneously pumping grout through the hollow bar. The drill bit advances the bar to design depth while grout fills voids. After reaching depth, the system is tensioned and locked with face plates and nuts.

Q: How do self drilling systems differ from traditional rock bolts?

A: Unlike conventional bolts requiring pre-drilled holes, self drilling systems combine drilling and anchoring. Their hollow design enables continuous grout injection during installation. This creates better load distribution and immediate ground support compared to sequential methods.

Post time: Apr . 29, 2025 12:31