Hex Socket Bolt 2024 Market & Technology Insights

Deep Dive: Trends, Specifications, Applications, Manufacturing & Industry Analysis

— The Science and Strategy behind Hex Socket Bolt Excellence

— The Science and Strategy behind Hex Socket Bolt Excellence

1. Industry Trends and Market Overview of Hex Socket Bolt

The Hex Socket Bolt is a fundamental mechanical fastener used across diverse sectors—including petrochemical, metallurgy, water supply & drainage, wind energy, and precision electronics—for its reliability, compact force-transmission, and superior ease of maintenance. Global demand surged by 6.8% CAGR from 2021-2023, reaching a market value of USD 2.87 billion in 2023 (Grand View Research).

- High-strength and corrosion-resistant hex socket bolts are seeing growing demand in critical infrastructure projects.

- Compliance with ISO 898-1 and ANSI B18.3 standards is a top industry requirement.

- Technological advances focus on CNC-milled precision and advanced surface coatings (zinc, HDG, PTFE).

Product link: Hex Socket Bolt | All specs, certifications & datasheets available.

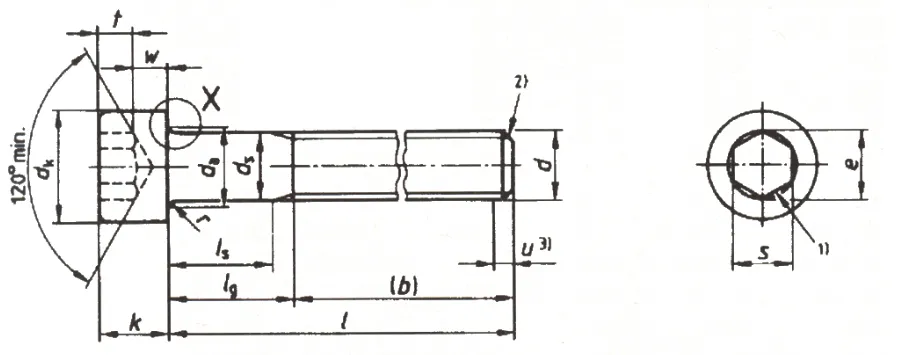

2. Technical Parameters & Product Specification Table

| Parameter | Common Value / Range | Standard | Remarks |

|---|---|---|---|

| Diameter (d) | M5 – M56 (#10– 2") |

ISO, ANSI | Metric & Inch series |

| Material | Alloy Steel, SS304/316, Brass, Titanium | ISO 898-1 ASTM A574 |

High strength/corrosion resistance |

| Tensile Strength | 600 – 1,200 MPa | ISO 898-1 | Grade 8.8/10.9/12.9 available |

| Thread | Coarse (UNC), Fine (UNF), Metric | ISO 261/262, ANSI B1.1 |

Custom threads on request |

| Surface Finish | Zinc, HDG, Black Oxide, PTFE | ISO 4042 ASTM F1941 |

Enhanced corrosion protection |

| Size Tolerance | ±0.01 mm | ISO 4759-1 | Precision-guaranteed via CNC |

| Operating Temp. | -40°C to +350°C | Manufacturer Test | Material-dependent |

All Hex Socket Bolt products fully comply with ISO 898-1, ISO 4042, ISO 261/262 and ANSI B18.3 standards.

3. Manufacturing Process: From Raw Material to Precision Hex Socket Bolt

Process Steps: Material Selection → Cutting → Forging → Precise CNC Machining → Surface Treatment & QC

- Material: High-toughness steel (A2/A4 SS, 40Cr, 35CrMo), sourced in compliance with ISO 898-1.

- Forging: State-of-the-art hot forging (for diameters ≥ M18) & cold forging (≤ M16) for grain refinement, high fatigue-resistance.

- CNC Machining: All contact faces (including the hex recess) finished under ±0.01mm tolerance.

- Surface: Proprietary zinc/HDG & immersion PTFE coatings, meeting ASTM F1941.

- Testing: Every lot 100% mechanical, dimensional, and anti-corrosion tests, with traceable QC records.

For a visual walkthrough, see a typical Hex Socket Bolt production line video (external resource).

4. Industry-Leading Technical Advantages of Hex Socket Bolt

- Ultra-compact load transfer: Hex socket head design allows effective torque application using an Allen/hex key, minimizing risk of stripping.

- Superior mechanical strength: Achieves Grade 12.9 (≥1,200 MPa) via vacuum heat treatment & controlled cooling, exceeding ISO 898-1 class.

- Advanced corrosion resistance: PTFE or HDG finish, with neutral salt-spray test results >1,000 hours (ASTM F1941).

- Longevity: 15+ years typical service life in oil & gas or wastewater use, per customer field data.

- Excellent fatigue endurance: Fine thread plus optimal shank-ra fillet reduces stress concentration (see data below).

- Universal application: Conforming to both DIN and ANSI specifications.

Tensile Strength & Corrosion Resistance Comparison

Tensile strength varies according to grade, finish, and material; coatings like PTFE and HDG also boost long-term corrosion resistance.

Fatigue Lifetime, Thread Types in Hex Socket Bolt (Cycles to Failure)

Fine-threaded Hex Socket Bolt offers up to 1.6 million cycles to fatigue failure—ideal for vibration-prone applications.

5. Comparative Analysis: Leading Hex Socket Bolt Manufacturers

| Brand / Supplier | Main Strength | Certifications | Lead Time | Custom Options |

|---|---|---|---|---|

| HBTBLS (China) | Full grades; fast delivery | ISO 9001, CE, SGS | 7–15 days | Yes (size, coating, logo) |

| Unbrako (USA) | Highest strength; alloy R&D | ISO, ASTM, ANSI | 20–40 days | Limited |

| Bumax (Sweden) | Premium stainless; anti-galling | ISO, DNV | 30–60 days | Yes (esp. marine) |

| Bossard (Swiss) | Global standards, logistics | ISO 9001/14001 | 15–30 days | Some (project-based) |

| Tensalloy (India) | Cost-effective | ISO 898, CE | 21–45 days | Yes (basic) |

- HBTBLS offers the best balance of large inventory, customization, and shortest lead times—backed by 18 years in international markets and collaboration with Fortune 500 engineering companies.

- Standard and third-party certifications, such as SGS and CE, are paramount for project compliance globally.

OEM/ODM available — consult Hex Socket Bolt solutions team for custom designs.

6. Customization, Delivery, and After-Sales Support

- Dimension/Finish: CNC-adaptable from M5 to M56, lengths up to 400mm; any plating (Zn, HDG, PTFE, Dacromet, color) on request.

- Packaging: Custom logo/label, pallet/box/kit packing for OEM.

- Delivery: Standard sizes ship within 7 days; custom orders 10–21 days, with online tracking.

- Warranty: 2 years minimum; 15-year durability documented for corrosion-resistant grades in actual projects.

- Technical support: Pre-installation consulting, torque calculation, and on-site guidance available worldwide.

Recent project case:

Application: Desalination plant (Middle East, 2023)

Bolt Spec: SS316 M24 × 200 mm, PTFE finish

Result: Maintained corrosion-free joints after 14 months, despite saline humidity conditions. Directly delivered to EPC contractor with full traceability and test reports.

Application: Desalination plant (Middle East, 2023)

Bolt Spec: SS316 M24 × 200 mm, PTFE finish

Result: Maintained corrosion-free joints after 14 months, despite saline humidity conditions. Directly delivered to EPC contractor with full traceability and test reports.

Customer feedback sample (Oil equipment importer, Germany): “HBTBLS hex socket bolts offered not only precise fit-out but a remarkable resistance to aggressive process chemicals. Test results matched the data sheet. The packaging, prompt shipping, and multi-lingual support streamlined site installation.”

7. Real-World Application Scenarios of Hex Socket Bolt

Key Industries & Use Cases

- Petrochemical: Critical pipeline flanges and reactor mounting, especially where access is tight.

- Wind Power & Solar Mounts: High-tension assemblies with fatigue cycles and salt spray exposure.

- Engineering Machinery: Gearbox housings, robotics arms; benefits from consistent preload and no head protrusion.

- Water Treatment: Corrosive wet environments using SS316 & PTFE hex socket bolts for pump stations.

- Precision Instrumentation: Cleanroom and test bench modules where strictly controlled tolerances are crucial.

Global Hex Socket Bolt Application Distribution 2023

Over 27% of global Hex Socket Bolt usage is in Energy & Utility installations; industrial, machinery, and water sectors are fast-growing.

8. Professional FAQ for Hex Socket Bolt (Terms vs. Field Questions)

Q1. Which material is optimal for severe corrosion environments?

A. SS316 or titanium Hex Socket Bolt with PTFE/Dacromet finish offer maximum resistance to chloride, acids, and seawater. SS316 is standard in marine and chemical plants.

Q2. What are most common thread standards?

A. Metric (ISO 261/262), Unified threads (UNC/UNF, ANSI B1.1) are standard. Metric threads are globally preferred for engineering consistency.

Q3. How to specify grade?

A. By ISO 898-1 (Grade 8.8, 10.9, or 12.9, etc.)—higher grade equals higher mechanical strength. Markings are usually head-stamped.

Q4. What are accepted installation torque standards?

A. Install per DIN 912/ISO 4762 torque charts (e.g., M16/10.9 = 190 Nm, lubricated). Use torque wrenches for critical assemblies.

Q5. Can I request non-standard lengths or heads?

A. Yes, fully customizable by CNC (hex, button, flanged, or low head); toleranced to ±0.01mm.

Q6. What is the standard finish for outdoor use?

A. Hot-Dip Galvanized (HDG) and PTFE/Fluoropolymer are top choices for weather-resistance per ASTM F2329.

Q7. Does the supplier provide full traceability and certificates?

A. Yes. Supply chain fully documented; MTC, inspection, and 3rd-party SGS or CE certificates are standard at delivery.

9. Delivery Periods, Support, and Quality Assurance

- Standard dispatch: 7–10 working days for warehouse models.

- Custom production: 14–28 days after technical drawing confirmation & deposit.

- Packaging: Export wooden palette or steel drums, moisture-proof, with all markings.

- Quality assurance: 24-month warranty for mechanical performance; free replacement for confirmed defects.

- Support: 24/7 customer engineering hotline, field support possible for major projects, multi-language team.

- Certifications: ISO 9001, CE, SGS; all products with unique trace code and full Mill Test Certificate (MTC).

10. References & Further Reading

- Grandview Research: Industrial Fasteners Market Report 2023

- Fastener World Magazine: www.fastener-world.com.tw

- ASTM International—F1941 Zinc Plating: www.astm.org/f1941_f1941m-21.html

- ISO Technical Standards for Mechanical Fasteners: ISO/TC 2 (Fasteners)

- Engineering Fastener Forum: www.eng-tips.com/threadminder.cfm?pid=730

- Bolt Design & Application Handbook, Fastener Technology International, 2023 Edition

For a comprehensive, certified Hex Socket Bolt quote or technical advice,

please visit https://www.hbtbls.com/hex-socket-bolt.html.

please visit https://www.hbtbls.com/hex-socket-bolt.html.

Post time: Jul . 30, 2025 07:00