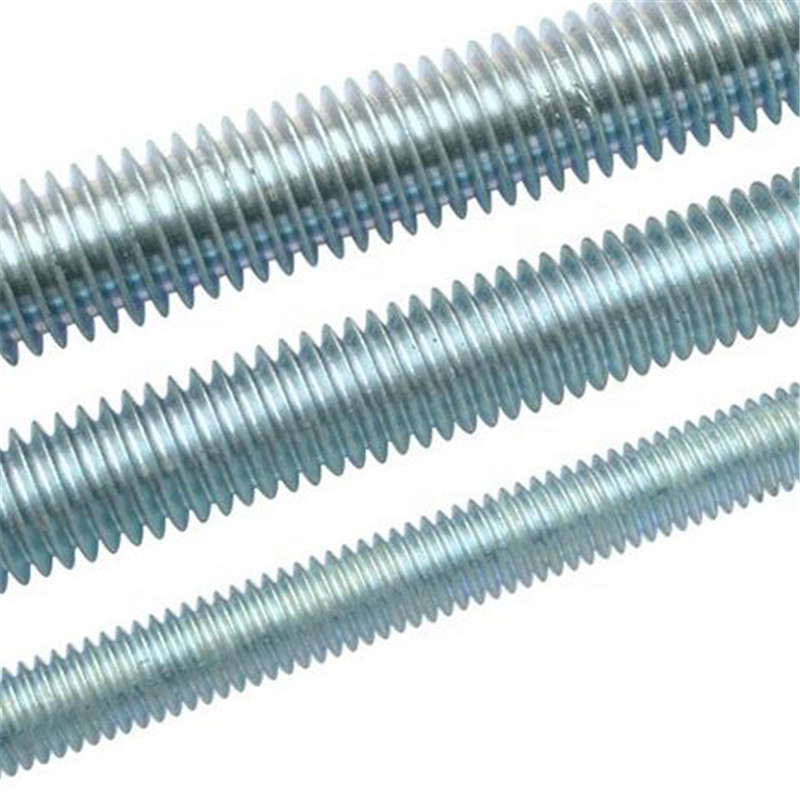

DIN975 threaded rod is one of the most fundamental fasteners in industrial construction, machinery, civil engineering, and infrastructure. As a globally recognized fastener, the DIN975 (also referred to as din975, din 975 10.9, din 975 4.8, din 975 8.8) establishes the gold standard for threaded connections. This in-depth guide, produced in collaboration with industry leader Yongnian Country Tianbang Fasteners Co., Ltd (Tianbang Fasteners), explores current market trends, technical parameters, professional applications, and authoritative references to help professionals make data-driven decisions.

Official Website: https://www.hbtbls.com

Tel: 18803303309

Mobile: 18803303309

Email: Karryyan@hbtbls.com

Address: Dongtantou North, Yongnian, Hebei, China

1. Product Overview: DIN975 Thread Rod

Product Name: DIN975 Thread Rod

Short Description: A threaded rod is a fastener and functions thanks to the threading, which causes a tightening action from the rotational movement. Threading on a rod allows other fixings like bolts and nuts to easily screw or fasten to it.

Product Site: DIN975 Threaded Rod Product Page

- Covers grades: DIN 975 4.8, DIN 975 8.8, DIN 975 10.9 - signaling a range of mechanical properties from general purpose to high strength.

- Applications: Steel structure assembly, mechanical engineering, electrical cabinets, automotive, oil & gas, HVAC, marine, bridge construction, and more.

- Compliance: Strict adherence to DIN, ISO, ASTM global standards.

2. Industry Trends & Market Overview

The demand for DIN975 threaded rod continues to surge. According to the Fastener World Magazine, the global threaded rod market, valued at USD 950 million in 2023, is projected to grow at a CAGR of 4.1% through 2029 (source). Increasing infrastructure investment in Asia-Pacific, Europe, and the adoption of automation in construction and factory settings drive demand for high-precision, high-strength rods like din 975 10.9.

- Stainless, zinc-plated, and galvanized variants are seeing rapid uptake for improved corrosion resistance.

- Sustainability and RoHS-compliance are trending priorities.

- Custom length and thread pitch customization are now standard in most manufacturing requests (BoltDepot).

3. Technical Parameters of DIN975 Threaded Rod

| Property | DIN 975 4.8 | DIN 975 8.8 | DIN 975 10.9 |

|---|---|---|---|

| Material | Carbon Steel (Class 4.8) | Alloy Steel (Class 8.8) | Alloy Steel (Class 10.9) |

| Tensile Strength (MPa) | 400 | 800 | 1000 |

| Yield Strength (MPa) | 320 | 640 | 900 |

| Finish | Zinc Plated / Plain | Plain / Black Oxide | Plain / Black Oxide / Galvanized |

| Standard Lengths | 1m, 2m, 3m | 1m, 2m, 3m | 1m, 2m, 3m |

| Thread | Metric | Metric | Metric |

| Common Applications | General Fastening & Bracing | Steel Fabrication, Heavy Machinery | Critical Load, Automotive, Structure |

4. Data Visualization: Technical Trends for DIN975 Threaded Rod

5. Typical Applications of DIN975 Threaded Rod

- Steel Structures: Used in bridges, towers, warehouses for bracing, anchor bolts, and supports.

- Building & Construction: Mounting, reinforcement, suspensions, and tension elements.

- Mechanical Engineering: Machinery assembly, conveyor systems, equipment mounting.

- Automotive & Transport: Chassis reinforcement, engine blocks, structural fastening.

- Electrical Installation: Distribution cabinets, cable trays, HVAC duct fixing.

- Oil & Gas: Pipeline bracing, offshore platforms, refinery systems.

- Renewable Energy: Solar and wind mounting frames.

- Marine & Shipbuilding: Superstructures and hull assemblies.

6. Professional Q&A on DIN975 Threaded Rod Technical Terms

A: The common grades include DIN 975 4.8 (medium-strength carbon steel), DIN 975 8.8 (high-strength structural steel), and DIN 975 10.9 (alloy steel for critical, high-load applications). Stainless steel options are also available for corrosive environments.

A: DIN975 threaded rod uses metric threads, typically M4 to M56, with coarse or fine pitch as per application. The pitch and tolerance follow DIN13 or ISO 965-1 standards (source).

A: For general construction and light mechanical loads, DIN 975 4.8 suffices. For higher mechanical stress and structural connections, DIN 975 8.8 is recommended. DIN 975 10.9 is ideal for heavy-duty applications and critical infrastructure.

A: Zinc-plating (blue/yellow), hot-dip galvanized, plain, and black oxide. For marine/corrosive environments, stainless steel or hot-dip galvanized rods are preferred. Finish selection impacts rust resistance and performance lifespan.

A: Installation should comply with torque and embedment depth specifications according to application standards (Europen EN14399, ASME B18.31.3). Use compatible nuts/washers per thread class to guarantee joint reliability (SKF Fastener Guidelines).

A: Yes! Yongnian Country Tianbang Fasteners Co., Ltd supports custom lengths (up to 6 meters) and special thread requirements (UNC, UNF, BS, etc.), complying with client engineering drawings.

A: Mechanical and chemical properties are verified via third-party laboratories, using standards like ISO 898-1, EN ISO 6506 (Brinell Hardness), and tensile machines. Inspection certificates and material traceability are provided with shipments.

7. Why Choose Yongnian Country Tianbang Fasteners Co., Ltd for Your DIN975 Threaded Rod Needs?

- Certified manufacturing facilities with ISO 9001:2015, ensuring traceable and reliable quality.

- Large-size and small-lot production flexibility—short lead times for both custom and standard DIN975 rods.

- Strict adherence to DIN, ASTM, and ISO protocols.

- Global export experience, logistics optimization, and expert technical consultation.

- Comprehensive after-services, including material certification and full documentation.

- Website: https://www.hbtbls.com

- Email: Karryyan@hbtbls.com

- Tel/WhatsApp: 18803303309

- Address: Dongtantou North, Yongnian, Hebei, China

8. Authoritativeness & EEAT: Industry References

- Manufacturing and technical insights referenced from Fastener World Magazine and Bolt Depot

- Standard specifics sourced from Engineering Toolbox and IFIS-ET Thread Rod Guide

- Installation guidelines per SKF Technical Guidelines

- Industry trend data courtesy of FastenerData.org

- Peer-reviewed content visible at ScienceDirect – Mechanical Behavior of Threaded Rods

For further reading on din975 threaded rod trends and to explore purchasing options, visit the official product page at Yongnian Country Tianbang Fasteners Co., Ltd, or explore major industry forums such as Eng-Tips Forums and Fasteners Clearing House.

Post time: Jul . 25, 2025 17:01