The Indispensable Role of Hex Socket Bolts in Modern Industry

In the intricate tapestry of modern industrial engineering, the integrity and reliability of every component are paramount. Among the myriad fastening solutions, the Hex Socket Bolt stands out as a fundamental, high-performance fastener. Its distinctive hexagonal recess for an Allen key (hex key) or hex bit drive allows for a more compact design and superior torque application compared to traditional external hex head bolts. This makes them indispensable in applications requiring flush mounting, reduced clearance, and high clamping forces. From heavy machinery to precision instruments, the demand for robust, reliable, and durable fastening solutions like the Hex Socket Bolt continues to grow, driven by advancements in material science, manufacturing precision, and the increasingly stringent performance requirements of global industries.

The current industrial landscape is characterized by a relentless pursuit of efficiency, safety, and longevity. This trend directly influences the design and application of fasteners. Industries such as renewable energy, aerospace, advanced robotics, and complex infrastructure projects are pushing the boundaries of what fasteners can achieve, demanding not only strength but also resistance to extreme environments, vibrations, and fatigue. The evolution of the Hex Socket Bolt reflects these demands, incorporating advanced materials, sophisticated manufacturing techniques, and rigorous quality control measures to meet the performance criteria of tomorrow's engineering challenges.

Unpacking the Hex Socket Bolt: Types and Core Advantages

A Hex Socket Bolt, often referred to as a socket head cap screw, is characterized by its cylindrical head and internal hexagonal drive. This design allows it to be installed using an Allen wrench, providing a high degree of control over the applied torque and preventing slippage. The internal drive system also means the head can be countersunk or flush with the mating surface, which is crucial for aesthetic and safety reasons, especially in moving parts or space-constrained assemblies.

Common Types of Hex Socket Bolts:

- Socket Head Cap Screws: The most common type, featuring a cylindrical head and internal hex drive. Ideal for precision assembly and high-strength applications.

- Socket Flat Head Cap Screws: Designed with a 90-degree conical under-head bearing surface, allowing them to sit flush with the surface when countersunk. Perfect for applications where aesthetics and a smooth surface are critical.

- Socket Button Head Cap Screws: Distinguished by their domed, low-profile head. While offering less tensile strength than standard socket head cap screws due to the shallower socket, they are preferred for their appearance and lower protrusion.

- Socket Set Screws: These are headless fasteners that are fully threaded and driven into a threaded hole, typically used to secure one object within another. They exert clamping force through compression rather than tension.

Core Advantages of Hex Socket Bolts:

- High Torque Application: The internal hex drive allows for greater torque to be applied without stripping the fastener head, ensuring a secure and reliable joint.

- Compact Design & Flush Mounting: The cylindrical or flat head design allows for installation in tight spaces and can be mounted flush with the surface, improving aesthetics and safety.

- Reduced Risk of Cam-out: The hex drive system significantly reduces the chances of the driver slipping out of the fastener head, enhancing installation efficiency and reducing fastener damage.

- Durability and Longevity: Often manufactured from high-grade alloy steel or stainless steel, these bolts offer excellent strength, fatigue resistance, and corrosion resistance, contributing to a longer service life in demanding environments.

- Versatility: Available in a wide range of sizes, materials, and finishes, making them suitable for diverse applications across numerous industries.

The Advanced Manufacturing Process of Hex Socket Bolts

The production of high-quality Hex Socket Bolt involves a sophisticated multi-stage manufacturing process that ensures precision, strength, and durability. This process typically combines material selection, cold forging, heat treatment, threading, and surface finishing, all under strict quality control protocols.

1. Material Selection: The Foundation of Strength

The performance of a Hex Socket Bolt begins with its material. Common materials include alloy steel (e.g., SAE J429 Grade 5 or 8, ASTM A574 for high-strength applications), stainless steel (e.g., 304, 316 for corrosion resistance), and sometimes exotic alloys for specialized needs. The choice of material dictates the bolt's mechanical properties, such as tensile strength, yield strength, and hardness, as well as its resistance to corrosion, temperature, and chemical exposure. Reputable manufacturers source raw materials from certified suppliers, ensuring traceability and adherence to international standards like ASTM and DIN.

2. Cold Forging (Cold Heading): Shaping with Precision

The primary method for forming the head and body of a Hex Socket Bolt is cold forging, also known as cold heading. This process involves forcing raw wire stock through a series of dies at room temperature. Cold forging realigns the grain structure of the metal, enhancing its tensile strength and fatigue resistance compared to machining alone. This multi-station cold former technique allows for rapid production of complex shapes, including the precise formation of the internal hex socket and the cylindrical head. The accuracy of the dies and the precision of the forging machinery are critical to achieving the tight tolerances required for proper fit and function.

3. Thread Rolling: Superior Thread Integrity

Unlike cut threads, which remove material, thread rolling forms the threads by plastically deforming the material. This process creates threads with superior strength, fatigue resistance, and surface finish. The grain structure of the material flows into the thread form, rather than being cut, resulting in stronger threads that are less prone to stripping or cracking under stress. This method is preferred for high-strength Hex Socket Bolt applications.

4. Heat Treatment: Enhancing Mechanical Properties

For alloy steel Hex Socket Bolt, heat treatment is a critical step to achieve the desired mechanical properties. This typically involves quenching and tempering. Quenching involves heating the bolts to a specific temperature and then rapidly cooling them in oil or water, which hardens the steel. Tempering follows, where the bolts are reheated to a lower temperature and then slowly cooled, which reduces brittleness and improves ductility and toughness while maintaining high strength. This process is precisely controlled to meet specific hardness and strength requirements, often defined by standards like ISO 898-1 or ASTM F835.

5. Surface Finishing and Coating: Protection and Performance

After heat treatment, Hex Socket Bolt often undergo surface finishing or coating processes to enhance their corrosion resistance, appearance, and friction characteristics. Common coatings include zinc plating (for basic corrosion protection), hot-dip galvanizing (for heavy-duty outdoor applications), black oxide (for mild corrosion resistance and aesthetic), and specialized coatings like Xylan or PTFE for extreme environments (e.g., enhanced corrosion resistance in marine or chemical processing industries, or reduced friction). These coatings are applied meticulously to ensure uniform coverage and adherence.

6. Quality Control and Inspection: Ensuring Compliance

Throughout the entire manufacturing process, stringent quality control measures are implemented. This includes:

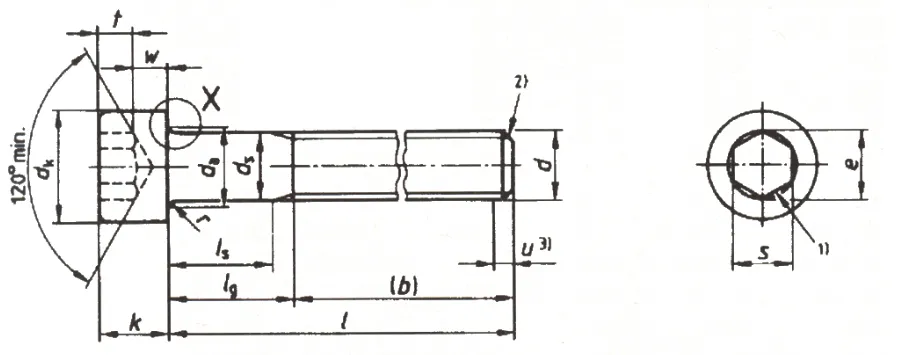

- Dimensional Inspection: Using precision tools like calipers, micrometers, and optical comparators to verify dimensions (length, diameter, head height, socket size, thread pitch) against standards like ISO 4762 (DIN 912) and ANSI/ASME B18.3.

- Mechanical Testing: Destructive tests such as tensile strength tests, yield strength tests, hardness tests (Rockwell, Brinell, Vickers), and impact tests (Charpy, Izod) are performed on samples to ensure mechanical properties meet specifications.

- Non-Destructive Testing (NDT): Techniques like magnetic particle inspection (MPI) or eddy current testing are used to detect surface or subsurface flaws without damaging the bolts.

- Coating Thickness Measurement: Ensuring the applied coatings meet the specified thickness and uniformity.

- Visual Inspection: Manual inspection for surface defects, burrs, or incomplete threads.

Adherence to international standards such as ISO 9001 for quality management systems is crucial. This comprehensive approach to manufacturing and quality control ensures that every Hex Socket Bolt delivered is of the highest quality, providing reliable performance and a long service life in its intended application. The average service life of a properly selected and installed Hex Socket Bolt can range from 10-20 years or more, depending on the environment, load cycles, and material chosen, especially when considering applications in static structures or non-corrosive environments. In highly dynamic or corrosive settings, life cycles are typically monitored through regular inspection and maintenance protocols.

Key Technical Parameters and Specifications of Hex Socket Bolts

Understanding the technical specifications of Hex Socket Bolt is crucial for proper selection and application. These parameters define the bolt's mechanical properties, dimensional compatibility, and suitability for specific environments. Below is a table outlining common technical parameters:

Table 1: Common Hex Socket Bolt Technical Specifications (ISO 4762 / DIN 912 & ASTM A574 Equivalent)

These parameters ensure that the selected Hex Socket Bolt meets the specific requirements of the application, including load-bearing capacity, environmental exposure, and operational longevity. For instance, in high-vibration environments, higher fatigue resistance is paramount, often achieved through specialized manufacturing processes and materials. In corrosive settings like chemical processing or marine applications, stainless steel (A4/316) or specialized coatings are essential to prevent premature failure.

Diverse Applications Across Key Industries

The versatility and robust performance of Hex Socket Bolt make them indispensable across a wide spectrum of industries. Their ability to deliver high clamping force in compact designs, coupled with their resistance to loosening, positions them as a preferred choice for critical applications.

Petrochemical and Oil & Gas Industry:

In the petrochemical and oil & gas sectors, equipment operates under extreme conditions including high temperatures, pressures, and exposure to corrosive chemicals. Hex Socket Bolt are extensively used in pipeline flanges, valve assemblies, pumps, compressors, and heat exchangers. Their high tensile strength ensures secure connections that can withstand internal pressures and vibrations, while the availability of corrosion-resistant materials (e.g., Duplex, Super Duplex, Inconel alloys) or specialized coatings (e.g., PTFE, Xylan) ensures longevity in highly aggressive environments, preventing leaks and catastrophic failures. This contributes directly to safety and operational efficiency, indirectly supporting energy saving by preventing process downtime.

Metallurgy and Heavy Machinery:

The metallurgy industry, encompassing steel mills, foundries, and heavy machinery manufacturing, relies on fasteners that can endure immense mechanical stress and thermal cycling. Hex Socket Bolt are integral to the assembly of rolling mills, continuous casting machines, industrial presses, and mining equipment. Their superior torque-bearing capacity ensures that heavy components remain securely fastened despite constant vibration and dynamic loads, minimizing downtime for maintenance and enhancing overall equipment reliability.

Water and Wastewater Treatment (WWT):

In water and wastewater treatment plants, exposure to water, various chemicals, and fluctuating temperatures necessitates highly corrosion-resistant fasteners. Hex Socket Bolt made from stainless steel (304, 316, or higher grades) are commonly used in pumps, valves, filtration systems, clarifiers, and piping networks. Their inherent corrosion resistance ensures the structural integrity of vital infrastructure, reducing maintenance costs and preventing environmental contamination. The ability to achieve flush mounts also aids in preventing accumulation of debris or microbial growth on surfaces.

Automotive and Aerospace:

Precision and safety are paramount in automotive and aerospace applications. Hex Socket Bolt are found in engine components, chassis assemblies, transmission systems, and various structural elements. In aerospace, where weight is a critical factor, specialized lightweight alloys like titanium are used for Hex Socket Bolt to secure crucial components, contributing to fuel efficiency and flight safety. The high shear strength and precise torque control offered by these fasteners are invaluable in these high-stakes environments.

Construction and Infrastructure:

From structural steel connections in bridges and high-rise buildings to façade systems and heavy equipment, Hex Socket Bolt provide robust and durable fastening solutions. Their ability to handle high tensile and shear loads is essential for maintaining the structural integrity of large-scale constructions. In pre-engineered buildings and modular construction, their ease of installation and high reliability streamline assembly processes.

In each of these industries, the choice of Hex Socket Bolt is highly specific, considering factors such as operating temperature, corrosive agents, vibration levels, and required service life. The ability of manufacturers to provide diverse materials, finishes, and customized dimensions ensures that the optimal fastener solution is deployed for every unique challenge.

Technical Advantages and Performance Benefits

The widespread adoption of Hex Socket Bolt across demanding industries is a testament to their inherent technical advantages and the significant performance benefits they offer. These benefits translate directly into enhanced reliability, reduced operational costs, and improved safety.

Superior Strength-to-Weight Ratio:

Due to their internal drive system and typically higher material grades (e.g., Class 12.9 alloy steel), Hex Socket Bolt can achieve very high tensile and shear strengths. This allows engineers to use smaller diameter bolts to achieve the same clamping force as larger external hex bolts, leading to lighter and more compact designs without compromising structural integrity. This is particularly beneficial in weight-sensitive applications like aerospace and robotics, where every gram counts.

Enhanced Corrosion Resistance:

While basic Hex Socket Bolt might be carbon steel with a simple zinc plating, advanced manufacturers offer these fasteners in a wide array of corrosion-resistant materials, including various grades of stainless steel (304, 316, Duplex, Super Duplex) and specialized alloys. Furthermore, advanced coatings such as PTFE (Teflon), Xylan, or ceramic coatings can provide exceptional resistance to aggressive chemicals, saltwater, and harsh industrial environments. This extends the service life of assemblies, reducing the frequency of costly maintenance and replacement.

Improved Resistance to Vibration and Loosening:

The design of the Hex Socket Bolt allows for precise torque application, minimizing the risk of under-tightening or over-tightening. When combined with proper torque settings and, if necessary, thread-locking compounds or locking washers, these bolts exhibit excellent resistance to loosening under dynamic loads and vibrations. This is critical in machinery that experiences constant movement, such as engines, vibratory equipment, and automotive suspensions, ensuring consistent performance and preventing catastrophic failures.

Aesthetic and Safety Benefits:

The flush-mount capability of socket head cap screws or the low profile of button head screws significantly improves the aesthetic appeal of an assembly. More importantly, this design reduces protrusions, minimizing snag hazards in machinery with moving parts, thereby enhancing worker safety. This smooth surface also makes them easier to clean and reduces areas where dirt or debris can accumulate, which is beneficial in sanitary or precision environments.

Ease of Installation and Maintenance:

Using an Allen key or hex bit allows for quick and efficient installation, even in confined spaces where a wrench might not fit. The internal drive prevents cam-out, reducing damage to the fastener head and improving installer productivity. For maintenance, the secure fit of the hex key ensures easy removal without stripping, even after prolonged service or exposure to challenging conditions.

In summary, the technical superiority of Hex Socket Bolt in terms of strength, corrosion resistance, vibration stability, and user-friendly design makes them an economical and reliable choice for demanding B2B applications, ultimately contributing to the longevity and efficiency of industrial systems.

Customization Solutions for Specific Project Needs

Standard off-the-shelf Hex Socket Bolt meet a wide range of industrial needs, but many advanced engineering projects require bespoke fastening solutions. Leading manufacturers understand this demand and offer comprehensive customization services to meet precise specifications, ensuring optimal performance in unique or highly challenging applications.

Material Customization:

Beyond standard alloy and stainless steels, custom Hex Socket Bolt can be manufactured from exotic alloys such as Inconel, Monel, Hastelloy, Titanium, or Duplex/Super Duplex stainless steels. These materials are chosen for their exceptional resistance to extreme temperatures, aggressive chemicals, high pressure, or unique mechanical properties, critical for applications in aerospace, chemical processing, or marine environments. For example, a specialized bolt for a subsea oil rig might require Super Duplex for its superior pitting and crevice corrosion resistance.

Dimensional and Thread Customization:

Projects often demand non-standard lengths, diameters, or thread pitches. Manufacturers can produce custom Hex Socket Bolt with specific thread forms (e.g., fine pitch, left-hand threads, specialized Acme threads), varying unthreaded shank lengths (shoulder bolts), or unique head dimensions to fit particular clearances or seating requirements. This flexibility ensures perfect integration with existing machinery or novel designs, eliminating the need for costly modifications to equipment.

Custom Coatings and Surface Treatments:

While standard coatings offer basic protection, custom solutions can include highly specialized surface treatments. This could involve application of proprietary anti-galling coatings for high-temperature applications, specific color-coded coatings for identification and aesthetic purposes, or conductive/non-conductive coatings for electrical insulation or grounding. Coatings can also be optimized for reduced friction, enhanced wear resistance, or specific torque-tension relationships during assembly.

Performance Specification Customization:

Some applications require a Hex Socket Bolt to meet specific performance criteria beyond standard mechanical properties, such as precise fatigue life under cyclical loading, guaranteed resistance to hydrogen embrittlement, or specific magnetic permeability. Manufacturers with advanced testing capabilities can develop and certify bolts to these stringent performance specifications, providing engineers with confidence in critical applications.

Design and Engineering Support:

A truly comprehensive customization service includes engineering consultation. This involves working closely with clients to understand their application requirements, performing finite element analysis (FEA) to validate designs, and offering material recommendations. This collaborative approach ensures that the customized Hex Socket Bolt is not just manufactured to spec, but is optimally designed for its intended function, maximizing performance and cost-effectiveness.

By leveraging these customization capabilities, businesses can acquire fastening solutions that are perfectly aligned with their project's unique demands, enhancing reliability, safety, and operational efficiency where standard products fall short.

Choosing the Right Manufacturer: A Comparative Analysis

Selecting the appropriate manufacturer for Hex Socket Bolt is a critical decision that impacts project timelines, operational reliability, and long-term cost-effectiveness. The market is saturated with suppliers, but discerning clients must look beyond mere price to evaluate key criteria that signify a truly reliable and high-quality partner.

Table 2: Manufacturer Comparison Checklist for Hex Socket Bolt Suppliers

While price is always a consideration, partnering with a manufacturer that excels in these areas guarantees not just the purchase of a Hex Socket Bolt, but an investment in reliable, high-performance fastening solutions that contribute to the overall success and safety of your operations. A strong manufacturer is a partner in engineering excellence, offering not just products but also technical expertise and robust support.

Real-World Application Cases: Hex Socket Bolt in Action

The theoretical advantages of Hex Socket Bolt are best understood through their successful deployment in challenging real-world scenarios. These case studies highlight their critical role in ensuring safety, efficiency, and longevity across diverse industrial applications.

Case Study 1: High-Pressure Valve Assembly in a Chemical Plant

Challenge: A major chemical processing plant faced recurring issues with flange leakage in their high-pressure, high-temperature (up to 300°C, 150 bar) acid lines. Traditional external hex bolts, despite being made of stainless steel, suffered from stress corrosion cracking and required frequent re-tightening due to vibration-induced loosening, leading to costly downtime and safety concerns.

Solution: The plant switched to using custom-manufactured Hex Socket Bolt made from Inconel 625 (a nickel-chromium-molybdenum alloy known for its excellent resistance to corrosion and high temperatures), with a specialized PTFE coating to reduce friction during assembly and enhance chemical resistance. The internal hex drive allowed for superior torque application and more consistent clamping force on the flanges. The bolts were installed with precise torque wrenches, and a small percentage were instrumented with load cells for real-time monitoring of preload.

Outcome: After one year of operation, there were zero instances of flange leakage. The enhanced corrosion resistance of Inconel 625 and the stable preload provided by the Hex Socket Bolt eliminated the need for routine re-tightening, reducing maintenance costs by an estimated 30% and significantly improving plant safety and operational uptime. The average service life of these critical fasteners was projected to exceed 15 years.

Case Study 2: Robotic Arm Assembly in Automotive Manufacturing

Challenge: An automotive assembly plant needed extremely reliable and compact fasteners for their next-generation welding robots. The robotic arms experience rapid, repetitive movements and high dynamic loads, leading to fatigue failures in the joints previously fastened with standard external hex bolts. Space constraints also limited the size of the fastening tools.

Solution: Engineers opted for high-strength alloy steel Hex Socket Bolt (Class 12.9) with a black oxide finish for minimal light reflection and good initial corrosion protection. The compact head design of the socket head cap screws allowed for flush mounting, reducing interference with other robotic components and enhancing the sleek design. Crucially, thread-locking patches were pre-applied to the bolts to resist vibration loosening. Automated torque-controlled systems were used for installation, ensuring precise and consistent preload across all critical joints.

Outcome: The implementation of the specialized Hex Socket Bolt resulted in a 90% reduction in fastener-related failures within the robotic arms over a two-year period. The improved fatigue resistance and resistance to vibration loosening significantly extended the operational life of the robots, leading to an increase in production line uptime by 7%, translating to millions in annual savings. The compact design also allowed for more agile robot movements and a more streamlined manufacturing process.

Case Study 3: Offshore Wind Turbine Structural Connections

Challenge: Offshore wind turbines are subjected to extreme environmental conditions, including constant saltwater spray, high winds, and continuous vibrations. Fasteners used in critical structural connections of the turbine tower and nacelle suffered from severe corrosion and fatigue, requiring frequent and costly inspections and replacements.

Solution: For critical structural connections, large-diameter, high-strength Hex Socket Bolt made from Duplex Stainless Steel (e.g., UNS S31803) were specified. These bolts provided superior resistance to chloride-induced stress corrosion cracking and pitting compared to conventional stainless steels. Additionally, a specialized anti-galling and anti-corrosion coating (such as a multi-layer ceramic-metallic coating) was applied to prevent seizing and further enhance durability. The internal hex drive facilitated easier installation and removal in confined spaces within the tower structure, allowing for precise tensioning of these critical joints.

Outcome: The use of these highly specialized Hex Socket Bolt significantly extended the inspection and maintenance intervals for the structural connections, reducing operational costs by approximately 20% over a 5-year period. The enhanced corrosion and fatigue resistance contributed directly to the long-term structural integrity of the wind turbines, ensuring stable energy production and extending the overall lifespan of these valuable assets, aligning with sustainable energy goals.

These cases demonstrate that investing in high-quality, application-specific Hex Socket Bolt solutions from a reputable manufacturer yields substantial long-term benefits in terms of reliability, safety, and operational cost savings.

Quality Assurance and Certifications: The Cornerstone of Trust

In the B2B sector, particularly for critical components like Hex Socket Bolt, quality assurance is not merely a formality but a fundamental pillar of trust and reliability. A manufacturer's adherence to stringent quality management systems and possession of relevant certifications are direct indicators of their commitment to delivering products that perform as expected, consistently and safely.

ISO 9001:2015 Certification:

This is the international standard for quality management systems. A manufacturer certified to ISO 9001 demonstrates their ability to consistently provide products and services that meet customer and regulatory requirements. For Hex Socket Bolt production, this means a documented process for everything from raw material procurement and cold forging to heat treatment, threading, surface finishing, and final inspection. It ensures traceability of materials and processes, giving customers confidence in the consistency and quality of their fasteners.

Compliance with Industry-Specific Standards:

- ASTM (American Society for Testing and Materials): Standards like ASTM A574 for alloy steel socket head cap screws define specific material properties, heat treatment requirements, and testing procedures. Compliance ensures the bolt meets defined strength and performance characteristics.

- ANSI/ASME (American National Standards Institute / American Society of Mechanical Engineers): Standards such as ANSI/ASME B18.3 cover dimensional requirements for socket cap, shoulder, and set screws. Adherence guarantees interchangeability and proper fit.

- ISO (International Organization for Standardization): ISO 4762 is the international standard for hex socket head cap screws, defining dimensions and mechanical properties. This is crucial for global interoperability.

- DIN (Deutsches Institut für Normung): While largely superseded by ISO, many older designs still reference DIN standards (e.g., DIN 912 for hex socket head cap screws). Manufacturers should be able to supply to these legacy standards if required.

- CE Marking: For products sold within the European Economic Area, the CE mark indicates conformity with health, safety, and environmental protection standards. While not always directly applicable to individual fasteners, it may be relevant for assemblies or specific fastener types.

- RoHS Compliance: Restriction of Hazardous Substances Directive is critical for many industries, particularly electronics and automotive, ensuring the fasteners do not contain certain hazardous materials.

Rigorous Testing Protocols:

Beyond certifications, manufacturers should implement comprehensive in-house testing. This includes:

- Mechanical Testing: Tensile strength, yield strength, elongation, reduction of area, hardness (Rockwell, Brinell), and impact testing are performed to verify the mechanical integrity of the Hex Socket Bolt.

- Metallurgical Analysis: Examining the microstructure of the material to ensure proper heat treatment and grain structure, and performing chemical analysis to confirm material composition.

- Dimensional Accuracy: Using calibrated instruments (e.g., optical comparators, profile projectors, go/no-go gauges) to verify that every dimension of the bolt adheres to drawing specifications and relevant standards.

- Corrosion Resistance Testing: Salt spray tests (e.g., ASTM B117) are commonly used to evaluate the effectiveness of coatings and the inherent corrosion resistance of materials.

- Non-Destructive Testing (NDT): For critical applications, NDT methods like magnetic particle inspection, ultrasonic testing, or eddy current testing are employed to detect hidden flaws or surface discontinuities.

A commitment to these standards and testing procedures minimizes the risk of product failure, ensures optimal performance, and provides a robust foundation of trustworthiness between the manufacturer and the end-user. Reputable manufacturers often provide Material Test Reports (MTRs) or Certificates of Conformance (CoC) with each shipment, documenting the compliance of the supplied Hex Socket Bolt.

Logistics, Delivery, and Comprehensive Customer Support

Beyond the product itself, the efficiency of logistics, reliability of delivery, and depth of customer support are crucial factors for B2B buyers of Hex Socket Bolt. In industrial settings, delays can be extremely costly, and technical issues require prompt, expert assistance.

Optimized Delivery Cycles:

Leading manufacturers of Hex Socket Bolt prioritize streamlined supply chains and efficient production planning to offer competitive delivery cycles. For standard products, this might mean ex-stock availability or lead times of 1-2 weeks. For custom or specialty bolts, lead times will naturally be longer, but a professional manufacturer will provide clear, realistic estimates, typically ranging from 4-8 weeks depending on complexity, material availability, and current production schedules. They often employ advanced ERP systems for inventory management and order tracking, allowing for real-time updates on order status and proactive communication regarding any potential delays. This precision in forecasting and execution is vital for customers to manage their own project timelines and minimize inventory holding costs.

Global Reach and Distribution Networks:

A robust manufacturer of Hex Socket Bolt often possesses a global distribution network, enabling them to serve clients worldwide efficiently. This includes partnerships with international freight forwarders, understanding of customs regulations, and optimized packaging for safe and secure transit, regardless of destination. For international clients, this global capability translates into reliable access to high-quality fasteners, regardless of geographical location, minimizing shipping costs and transit times.

Dedicated Customer and Technical Support:

Exceptional customer support extends beyond simply taking orders. It involves:

- Pre-Sales Consultation: Providing expert advice on material selection, coating options, and dimensional requirements for specific applications of Hex Socket Bolt. This proactive support helps clients make informed decisions and avoid potential issues.

- Post-Sales Technical Assistance: Offering support for installation best practices, torque specifications, troubleshooting any performance issues, and guidance on maintenance. A responsive technical team can be invaluable in critical situations.

- Responsive Communication: Clear and timely communication regarding order status, shipping updates, and any unforeseen challenges.

Robust Warranty and After-Sales Commitment:

A confident manufacturer stands behind their products. This is demonstrated through clear warranty policies that cover manufacturing defects and material failures. Beyond a warranty, a commitment to ongoing customer satisfaction through responsive claims processing and a willingness to investigate and resolve issues reinforces trustworthiness. This commitment provides peace of mind, knowing that the investment in high-quality Hex Socket Bolt is protected.

Ultimately, a manufacturer that excels in logistics, delivery, and customer support transforms from a mere supplier into a valuable strategic partner, contributing significantly to the smooth operation and success of a client's projects.

Frequently Asked Questions (FAQ) about Hex Socket Bolt

Q1: What is the primary advantage of a Hex Socket Bolt over a standard external hex bolt?

A1: The main advantage lies in its internal hex drive, which allows for a higher torque application without stripping the head, and enables flush mounting or placement in tighter spaces. This contributes to a cleaner aesthetic, reduced snag hazards, and superior clamping force in compact designs.

Q2: How does cold forging impact the performance of a Hex Socket Bolt?

A2: Cold forging (cold heading) strengthens the bolt by realigning the metal's grain structure, making it more resistant to fatigue and increasing its tensile strength compared to bolts made by machining. This process ensures the structural integrity and longevity of the fastener, especially under dynamic loads.

Q3: What are common materials used for Hex Socket Bolt and when are they chosen?

A3: Common materials include alloy steel (for high strength, often heat-treated to Class 10.9 or 12.9) and stainless steel (304 for general corrosion resistance, 316 for enhanced resistance in aggressive environments like marine or chemical processing). Exotic alloys like Inconel or Titanium are used for extreme temperature, highly corrosive, or weight-sensitive aerospace applications.

Q4: Can Hex Socket Bolt be customized for specific industrial applications?

A4: Absolutely. Reputable manufacturers offer extensive customization options, including specific materials (e.g., aerospace alloys), non-standard dimensions, unique thread types, and specialized coatings (e.g., PTFE, Xylan) to meet exact performance requirements for challenging environments or bespoke designs.

Q5: How do manufacturers ensure the quality and reliability of their Hex Socket Bolt?

A5: Quality is ensured through adherence to international standards (e.g., ISO 9001, ASTM, ISO 4762), rigorous in-house testing (tensile, hardness, corrosion, dimensional accuracy), and comprehensive material traceability. Many also provide Material Test Reports (MTRs) for verification.

Q6: What is the typical service life of a Hex Socket Bolt?

A6: The service life varies significantly depending on the material, application environment (e.g., corrosive, high-vibration), proper installation, and load cycles. In ideal conditions, a high-quality Hex Socket Bolt can last 10-20 years or more. For critical dynamic applications, regular inspections and adherence to maintenance schedules are crucial.

Conclusion: Securing the Future with Advanced Hex Socket Bolt Solutions

The Hex Socket Bolt stands as a testament to precision engineering and material science, playing an unassuming yet critically important role across the vast landscape of industrial applications. Its unique design offers unparalleled advantages in terms of high strength, compact installation, and superior torque control, making it an indispensable component in everything from heavy machinery and critical infrastructure to advanced robotics and aerospace systems. The continuous innovation in materials, manufacturing processes, and surface treatments ensures that the Hex Socket Bolt will continue to meet the evolving demands of increasingly complex and challenging industrial environments.

For B2B decision-makers and technical professionals, selecting the right Hex Socket Bolt is more than a procurement decision; it is a strategic investment in the reliability, safety, and longevity of their operations. Partnering with a manufacturer that not only adheres to the highest quality standards (ISO, ASTM, DIN) but also offers extensive customization capabilities, robust quality assurance protocols, and dedicated customer support, is paramount. Such a partnership guarantees access to fasteners that are not just compliant, but engineered for optimal performance, contributing significantly to reduced downtime, lower maintenance costs, and enhanced overall operational efficiency. As industries continue to advance, the demand for sophisticated and reliable fastening solutions will only grow, solidifying the enduring importance of the Hex Socket Bolt as a cornerstone of modern engineering.

References

- ISO. (2021). ISO 4762:2021 Hexagon socket head cap screws. International Organization for Standardization.

- ASTM International. (2023). ASTM A574: Standard Specification for Alloy Steel Socket-Head Cap Screws (Metric). ASTM International.

- Fagrell, A. (2018). Fastener Design Manual. NASA Reference Publication 1228.

- Schwartz, M. M. (2019). Mechanical Fastening, Joining, and Assembly. CRC Press.

- Kulak, G. L., Fisher, J. W., & Struik, J. H. A. (2001). Guide to Design Criteria for Bolted and Riveted Joints. American Institute of Steel Construction.

Post time: Aug . 21, 2025 22:40