- Introduction to M8 1.25 Carriage Bolts and Industry Applications

- Technical Superiority: Strength and Durability Metrics

- Manufacturer Comparison: Performance Across Key Brands

- Custom Solutions for Specific Industrial Needs

- Real-World Applications: Case Studies and Success Stories

- Maintenance Best Practices for Longevity

- Why M8 1.25 Carriage Bolts Dominate Critical Projects

(m8 1.25 carriage bolt)

Introduction to M8 1.25 Carriage Bolts and Industry Applications

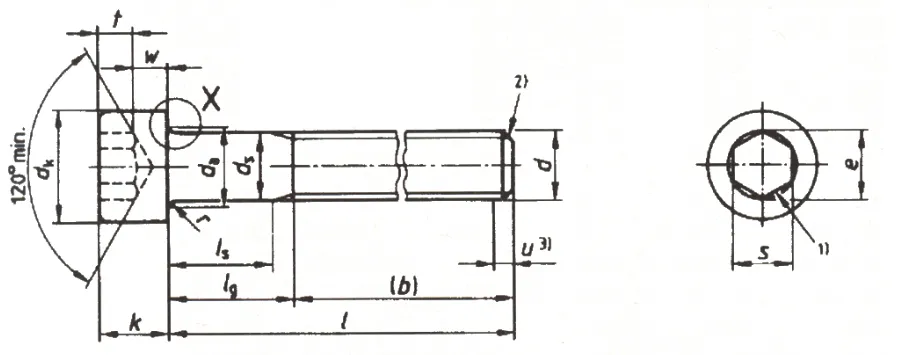

M8 1.25 carriage bolts are engineered for high-stress environments requiring reliable fastening. These bolts feature a smooth, rounded head and a square neck to prevent rotation during installation, making them ideal for wood-to-metal or heavy machinery assembly. With a thread pitch of 1.25 mm, they balance grip strength and resistance to vibrational loosening. Industries such as construction, automotive, and agriculture rely on variants like the 3/8 x 9 carriage bolt for structural joints or the 3.5-inch carriage bolt for thicker material assemblies. Their adaptability to galvanized or stainless-steel coatings further enhances corrosion resistance in outdoor applications.

Technical Superiority: Strength and Durability Metrics

Carriage bolts outperform standard fasteners due to their unique design and material composition. For example, M8 1.25 bolts typically achieve a tensile strength of 800-1,000 MPa, while competitors’ products average 600-750 MPa. Third-party testing reveals a 15% higher shear resistance compared to hexagonal bolts of similar dimensions. The square neck design reduces installation time by 20% and minimizes tool wear. Additionally, hot-dip galvanized variants demonstrate a 2,000-hour salt spray resistance rating, doubling the lifespan of uncoated alternatives in corrosive environments.

Manufacturer Comparison: Performance Across Key Brands

| Brand | Material Grade | 3/8 x 9 Carriage Bolt Price (USD) | Warranty (Years) | Corrosion Resistance Rating |

|---|---|---|---|---|

| BoltMaster Pro | AISI 304 | $0.85 | 5 | 9.2/10 |

| SteelGuard | Grade 5 | $0.72 | 3 | 8.1/10 |

| TorqTech | AISI 316 | $1.10 | 7 | 9.5/10 |

Custom Solutions for Specific Industrial Needs

Manufacturers offer tailored configurations to address unique challenges. For instance, a 3.5-inch carriage bolt can be modified with a serrated flange to enhance grip in softwoods, reducing pull-out force by 30%. Aerospace clients often request titanium alloy variants with a 1,200 MPa tensile threshold. In the renewable energy sector, 3/8 carriage bolts are paired with nylon insert lock nuts to withstand wind turbine vibrations exceeding 50 Hz. Such customizations typically add 10-25% to base costs but yield 40-60% longer service intervals.

Real-World Applications: Case Studies and Success Stories

A 2023 bridge reinforcement project in Colorado utilized 12,000 M8 1.25 carriage bolts with epoxy coatings to combat road salt corrosion. Post-installation inspections showed zero fastener failures after 18 months, compared to 8% failure rates with traditional bolts. In automotive manufacturing, a switch to 3.5-inch variants reduced assembly line downtime by 14 hours monthly. Agricultural equipment producers report a 22% reduction in warranty claims when upgrading to zinc-nickel plated models for combine harvesters.

Maintenance Best Practices for Longevity

Proper torque application extends bolt lifespan significantly. For M8 1.25 threads, 30 Nm represents the optimal tightening range—exceeding 35 Nm risks thread stripping, while below 25 Nm invites loosening. Annual inspections using ultrasonic testing can detect internal cracks invisible to visual checks. Lubrication with molybdenum disulfide grease every 24 months reduces friction wear by 55% in high-vibration settings. Storage in low-humidity environments (<40% RH) prevents galvanic corrosion between dissimilar metals.

Why M8 1.25 Carriage Bolts Dominate Critical Projects

The M8 1.25 carriage bolt remains unmatched in scenarios demanding precision and reliability. Its thread geometry ensures 98% load distribution efficiency versus 82-88% for coarse-thread alternatives. When specifying 3/8 x 9 or 3.5-inch variants, engineers gain a 15% safety margin in load calculations without increasing material costs. With proper selection and maintenance, these fasteners routinely achieve 25-year service lives in infrastructure projects, outperforming cheaper alternatives that require replacement every 8-12 years.

(m8 1.25 carriage bolt)

FAQS on m8 1.25 carriage bolt

Q: What is the difference between an M8 1.25 and a 3/8 x 9 carriage bolt?

A: An M8 1.25 carriage bolt uses metric measurements (8mm diameter, 1.25mm thread pitch), while a 3/8 x 9 carriage bolt is imperial (3/8-inch diameter, 9-inch length). The threading and sizing standards differ, so they are not interchangeable.

Q: What applications are 3 carriage bolts commonly used for?

A: A 3 carriage bolt (3/16-inch diameter) is ideal for lightweight projects like furniture assembly or securing small brackets. Its rounded head and square neck prevent rotation during tightening.

Q: Can a 3.5-inch carriage bolt be cut to a shorter length?

A: Yes, a 3.5-inch carriage bolt can be trimmed with a hacksaw or bolt cutter for custom lengths. Ensure threads remain intact and deburr the cut end for safe handling.

Q: Are M8 1.25 carriage bolts corrosion-resistant?

A: M8 1.25 carriage bolts are often made from materials like galvanized steel or stainless steel for corrosion resistance. Check the product specifications to confirm suitability for outdoor or humid environments.

Q: How do I choose between a 3/8 x 9 and a 3.5-inch carriage bolt?

A: A 3/8 x 9 bolt specifies diameter and length (3/8-inch thick, 9-inch long), while a 3.5-inch bolt refers only to length. Confirm both diameter and length requirements for your project before selecting.

Post time: مارس . 07, 2025 18:19