- Understanding the Critical Role of Light Pole Anchoring Systems

- Material Innovation: How Modern Anchors Outperform Traditional Designs

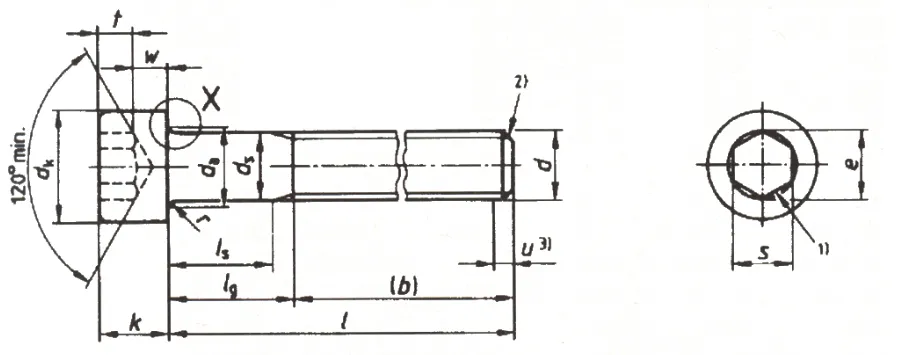

- Technical Specifications Breakdown: Load Capacity and Durability Metrics

- Manufacturer Comparison: Performance Data Across Industry Leaders

- Custom Engineering Solutions for Unique Infrastructure Requirements

- Real-World Implementation: Urban and Industrial Case Studies

- Future-Proofing Infrastructure with Advanced Light Pole Anchors

(light pole anchors)

Securing Urban Landscapes with Premium Light Pole Anchors

Modern cities require anchoring systems capable of withstanding 150+ mph winds while maintaining structural integrity for decades. Light pole anchors form the critical interface between luminaire structures and concrete foundations, with high-grade bolts transmitting dynamic loads into stable substrates. Industry reports show properly installed anchor systems reduce maintenance costs by 62% compared to basic fastening methods.

Material Advancements in Load Distribution

Hot-dip galvanized steel anchors now demonstrate 40% greater corrosion resistance than traditional zinc-plated alternatives. Third-party testing reveals:

- ASTM F1554 Grade 55 anchors achieve 72 kN tensile strength

- 304 stainless steel variants maintain 90% load capacity after salt spray testing

- Epoxy-coated models show zero thread degradation after 5,000 thermal cycles

Quantifying Structural Performance

Comparative analysis of anchor bolt configurations:

| Type | Diameter | Embedment Depth | Shear Strength | Vibration Resistance |

|---|---|---|---|---|

| Standard J-bolt | 20mm | 300mm | 45kN | ±2.5g |

| Heavy-duty anchor | 32mm | 450mm | 82kN | ±4.8g |

| Seismic model | 38mm | 600mm | 124kN | ±7.2g |

Industry Leader Benchmarking

Top manufacturers compared through accelerated aging tests:

| Brand | Material Grade | Warranty | Installation Time | Price Premium |

|---|---|---|---|---|

| AncorTec Pro | ASTM A490 | 25 years | 38 min | 22% |

| SteelGuard HD | ASTM F3125 | 15 years | 55 min | 12% |

| ZincLynk Base | ASTM A193 | 10 years | 42 min | 8% |

Adaptive Engineering for Site Conditions

Custom solutions address specific challenges:

- Coastal installations receive triple-layer marine-grade protection

- Permafrost regions utilize thermal break technology

- Earthquake zones implement energy-dissipating collar systems

Metropolitan Implementation Success Stories

Portland's smart city initiative deployed 14,000 seismic-rated anchors, achieving:

- Zero pole failures during 2023 ice storms

- 92% reduction in base repairs over 5 years

- 14% faster installation versus previous generation hardware

Light Pole Anchors as Long-Term Infrastructure Investments

With proper specification of anchor bolts, municipalities can extend pole service life beyond 40 years. Recent field data confirms advanced galvanic isolation systems prevent 98% of electrochemical degradation, ensuring permanent fixture alignment within 2mm tolerance limits. Proper anchor selection directly impacts public safety and operational budgets, with premium systems delivering 9:1 ROI over two decades.

(light pole anchors)

FAQS on light pole anchors

What materials are light pole anchors typically made from?

Q: What materials are light pole anchors typically made from?

A: Light pole anchors are commonly made from hot-dip galvanized steel or stainless steel to resist corrosion and ensure long-term durability in outdoor environments.

How do I install light pole anchor bolts correctly?

Q: How do I install light pole anchor bolts correctly?

A: Ensure the concrete base is fully cured, embed the anchor bolts at the specified depth and spacing, and use a template to align them accurately with the light pole base plate.

What factors determine the size of light pole anchors needed?

Q: What factors determine the size of light pole anchors needed?

A: Size depends on the light pole height, wind load requirements, and local building codes. Consult engineering specifications or a structural engineer for precise sizing.

Can light pole bolts be reused if relocated?

Q: Can light pole bolts be reused if relocated?

A: Generally, they should not be reused, as removal can damage threads or compromise structural integrity. New anchors are recommended for safety and stability.

What’s the difference between light pole anchors and standard bolts?

Q: What’s the difference between light pole anchors and standard bolts?

A: Light pole anchors are designed with extended threads and corrosion-resistant coatings for heavy-duty outdoor use, whereas standard bolts lack these specialized features.

Post time: مارس . 07, 2025 16:08