Leading the advancement in fastener technology and global manufacturing of Flange Bolt.

Mobile: 18803303309

Address: Dongtantou North, Yongnian, Hebei, China

Visit our site: https://www.hbtbls.com

Introduction: The Evolution and Impact of Flange Bolt

In the fast-paced world of industrial engineering and construction, the Flange Bolt stands out as a revolutionary advancement in fastening solutions. Integrating an innovative circular flange beneath the bolt head, this design eliminates the need for separate washers, offering enhanced torque distribution and rigidity. As sectors like automotive, machinery, aerospace, energy, and infrastructure pursue both reliability and cost efficiency, Flange Bolts have emerged as the preferred choice globally.

For manufacturers, quality standards and technological precision are now more important than ever—an ethos embodied by Yongnian Country Tianbang Fasteners Co., Ltd, a company known for its technical expertise, commitment to quality, and worldwide reach in the fastener industry.

Flange Bolt Product Overview

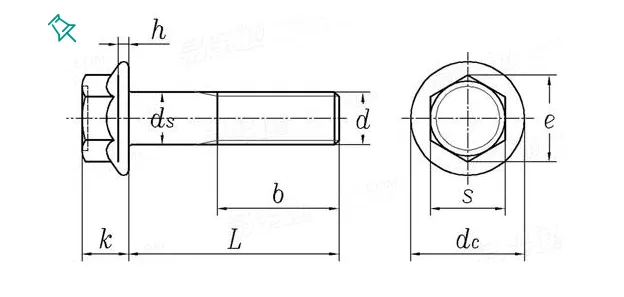

Flange Bolt products, offered by Yongnian Country Tianbang Fasteners Co., Ltd, represent the pinnacle of fastening innovation. The hallmark of this product is its integrated flange directly beneath the head, which distributes the load evenly and provides a robust, unified fastening system. Get all details and technical specifications directly at

product page.

- Key Features:

• Integrated circular flange for load distribution and anti-loosening effect.

• Eliminates the need for separate washers.

• Enhanced assembly efficiency and operational performance.

• Excellent in high-vibration and challenging environments.

• Supports a broad range of customization in material and finish.

Industry Trends in the Flange Bolt Market

As global industries progress towards automation, lightweight structures, and ecological responsibility, the fastener landscape is evolving remarkably. Notably, Flange Bolt adoption is surging, especially in high-performance automotive, wind and hydropower, marine, railway, and heavy industrial segments.

Key Trends:

- Expansion into electric vehicle, renewable energy, and aerospace markets

- Demand for corrosion-resistant, high-strength alloys (e.g., A2/A4 Stainless Steel, Grade 8.8–12.9 carbon/alloy steel)

- Innovation in anti-seize and anti-vibration design

- Stricter conformity to international standards—ISO, ASTM, DIN

- Increasing customization for smart assembly systems

Technical Specification Table: Flange Bolt (Sample Data)

| Parameter | Spec 1 | Spec 2 | Spec 3 | Spec 4 | Spec 5 |

|---|---|---|---|---|---|

| Thread Size (mm) | M6 | M8 | M10 | M12 | M16 |

| Length (mm) | 16–50 | 16–60 | 20–80 | 25–100 | 30–200 |

| Flange Diameter (mm) | 14.2 | 17.7 | 21.3 | 26.0 | 35.0 |

| Material | Carbon Steel | Stainless Steel | Alloy Steel | Brass | Custom (Exotic Alloys) |

| Strength Grade | 8.8 | 10.9 | 12.9 | A2-70 | A4-80 |

| Finish | Plain | Zinc Plated | Galvanized | Black Oxide | Dacromet |

| Standard | DIN 6921 | ISO 4162 | JIS B1189 | GB5787/5789 | Custom |

Key Application Scenarios for Flange Bolt

- Automobile Manufacturing: Chassis, engine assembly, transmissions—demanding vibration resistance and high durability.

- Heavy Machinery: Ensures operational integrity under dynamic/static loads and harsh conditions.

- Railroad Engineering: Track-laying and carriage systems benefit from unified torquing properties.

- Aerospace & Aviation: Lightweight alloys used in airframes and engine assemblies.

- Renewable Energy: Essential for wind turbines, solar panel mountings and hydropower mechanicals.

- Marine & Offshore: Corrosion-resistant versions for hulls, engines, and offshore platforms.

- Construction & Steel Structures: Bolted joints for bridges, towers, and steel structures for ultimate fastener reliability.

Why Choose Yongnian Country Tianbang Fasteners Co., Ltd for Flange Bolt Solutions?

- Decades of Expertise: Deep industry experience and globally certified production.

- Advanced Quality Management: Full traceability, ISO/DIN compliance, and process-controlled manufacturing.

- Customization Capability: Diverse materials, finishes, and non-standard specifications upon request.

- Global Reach: Export to over 60 countries, with robust logistics and after-sales support.

- Professional Technical Service: In-house engineering to support R&D, assembly optimization, and joint design.

Q&A: Professional Terminologies in Flange Bolt

(DIN 6921)

Strategic Advantages of Flange Bolt Design

- Cost-Effectiveness: Reduces component count, lowers assembly cost, and minimizes inventory SKUs.

- Productivity: Faster installation and disassembly, especially for assembly line and field work.

- Safety & Quality Assurance: Retains pre-load, reduces risk of bolt loosening and joint failure.

- Versatility: Multiple head/flange types (hex, 12Pt, spline, hollow) and finishes to match every application.

EEAT: Professional, Authoritative & Trusted Source

Yongnian Country Tianbang Fasteners Co., Ltd excels through decades of specialized fastener production, strict compliance with international standards, and continuous R&D.

The technical content and data here are aligned with leading fastener industry publications, scholarly forums, and global standards organizations:

Post time: ივლ . 26, 2025 12:01