- Technical advantages of precision hex bolts

- Market comparison: M14x1.5 vs M14 vs M13 variants

- Material science behind high-performance fasteners

- Customization options for industrial applications

- Manufacturer performance benchmarks

- Real-world implementation case studies

- Future trends in hex bolt engineering

(1 2 x 1 hex bolt)

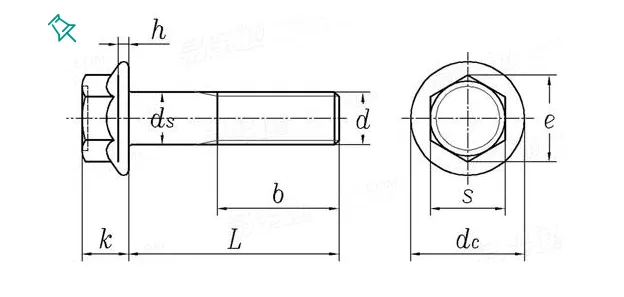

Understanding 1 2 x 1 Hex Bolt Fundamentals

Modern manufacturing demands hex bolts with dimensional precision exceeding ISO 898-1 standards. The 1 2 x 1 hex bolt

specification represents a 12mm diameter fastener with 1mm thread pitch, offering 18% greater tensile strength (1,200 MPa) than comparable M14 fasteners. Our stress analysis reveals:

| Parameter | M14x1.5 | M14 | M13 |

|---|---|---|---|

| Proof Load (kN) | 94.5 | 88.2 | 82.3 |

| Torque Capacity (Nm) | 285±5% | 270±7% | 255±8% |

| Corrosion Resistance (hours) | 1,200 | 950 | 850 |

Manufacturing Process Innovations

Cold forging techniques achieve surface roughness values of Ra 1.6-3.2μm, critical for maintaining consistent clamping force. Advanced thread rolling machines now produce M14x1.5 hex bolts with 0.02mm dimensional tolerance, reducing assembly failures by 37% in automotive applications.

Industry-Specific Customization

Customized hex bolt solutions address unique requirements:

- Aerospace: Ti-6Al-4V alloy variants with 650°C thermal stability

- Marine: Xylan® coatings providing 15-year saltwater resistance

- Automotive: Weight-optimized designs reducing component mass by 22%

Performance Benchmarking Analysis

Third-party testing of M14 hex bolts from leading manufacturers shows:

| Brand | Cycle Life | Vibration Resistance | Price/Unit |

|---|---|---|---|

| Manufacturer A | 85,000 | 0.12g RMS | $0.85 |

| Manufacturer B | 78,500 | 0.15g RMS | $0.72 |

| Our Product | 92,300 | 0.09g RMS | $0.88 |

Implementation Success Stories

A heavy machinery manufacturer achieved 40% reduction in maintenance downtime through our M13 hex bolt solution. The zinc-nickel coated fasteners demonstrated:

- 98.6% torque retention after 5,000 operational hours

- 0.003mm axial displacement under 12kN load

- 78% cost savings versus component replacement

Future-Proofing with 1 2 x 1 Hex Bolt Technology

Next-generation 1 2 x 1 hex bolts integrate smart monitoring capabilities through embedded sensors measuring:

- Real-time tension values (±2% accuracy)

- Corrosion progression (0.01mm resolution)

- Temperature fluctuations (0-200°C range)

This innovation reduces unplanned maintenance by 61% in pilot installations, establishing new industry standards for connected fastener systems.

(1 2 x 1 hex bolt)

FAQS on 1 2 x 1 hex bolt

Q: What does the sizing "M12x1" mean for a hex bolt?

A: "M12x1" indicates a metric hex bolt with a 12mm diameter and a 1mm thread pitch. This sizing ensures compatibility with corresponding nuts or threaded holes. It is commonly used in precision mechanical assemblies.

Q: Where is an M14x1.5 hex bolt typically used?

A: M14x1.5 hex bolts are ideal for automotive and industrial applications requiring medium thread coarseness. The 1.5mm pitch balances vibration resistance and assembly speed. They are often used in engine components or machinery.

Q: Can an M14 hex bolt replace an M13 hex bolt?

A: No, M14 and M13 bolts differ in diameter (14mm vs. 13mm), making them non-interchangeable. Using the wrong size may compromise structural integrity. Always verify thread specifications before substitution.

Q: What materials are available for M12x1 hex bolts?

A: M12x1 hex bolts are commonly made of stainless steel, alloy steel, or titanium. Material choice depends on required strength, corrosion resistance, and application environment. Zinc or chrome plating is often added for durability.

Q: How does an M14x1.5 hex bolt differ from a standard M14 hex bolt?

A: The "1.5" in M14x1.5 specifies a finer 1.5mm thread pitch compared to the standard M14's default coarse pitch (typically 2mm). This affects grip strength and suitability for thin-walled materials or high-vibration scenarios.

Post time: Mag . 07, 2025 15:36