- Overview of Hex Screw Nuts and Their Industrial Significance

- Technical Specifications and Load-Bearing Performance

- Material Science: Corrosion Resistance and Durability

- Market Analysis: Leading Manufacturers Compared

- Customization Options for Industry-Specific Demands

- Real-World Applications in Construction and Machinery

- Future Trends in Hex Screw Nut Manufacturing

(hex screw nut)

Understanding Hex Screw Nuts for Precision Fastening

Hex screw nuts, also known as hex nuts or machine screw nuts, are six-sided fasteners designed to distribute mechanical stress evenly across threaded joints. Industry surveys indicate a 12% annual growth in demand for ASME B18.2.2-compliant hex nuts, driven by advancements in aerospace and renewable energy sectors. These components typically withstand tensile loads ranging from 1,200 MPa to 1,800 MPa, making them critical for structural integrity in high-vibration environments.

Technical Specifications and Load-Bearing Performance

Modern hex nuts exceed ISO 4032 standards through innovative thread-locking geometries. Third-party testing data reveals:

| Grade | Proof Load (MPa) | Temperature Range | Vibration Resistance |

|---|---|---|---|

| Grade 5 | 1,200 | -50°C to 150°C | 2,000 hours @ 35Hz |

| Grade 8 | 1,800 | -75°C to 260°C | 3,500 hours @ 50Hz |

Electroplated zinc-nickel coatings now provide 2,000-hour salt spray resistance, doubling traditional galvanization performance.

Material Innovation in Corrosion Prevention

AISI 316L stainless steel variants demonstrate 98% corrosion resistance after 5-year marine exposure trials. Recent developments include:

- Self-healing polymer coatings reducing maintenance costs by 40%

- Laser-etched identification marks with 0.01mm precision

- Magnetic permeability below 1.05 μ for MRI-compatible installations

Manufacturer Comparison: Quality vs. Cost Efficiency

Data from Q3 2023 procurement reports shows:

| Supplier | Lead Time | MOQ | Defect Rate |

|---|---|---|---|

| Supplier A | 14 days | 5,000 units | 0.12% |

| Supplier B | 21 days | 2,000 units | 0.08% |

Automated quality inspection systems have reduced manufacturing variances to ±0.003mm across top-tier producers.

Tailored Solutions for Specialized Industries

Customization services now cover:

- Non-magnetic alloys for semiconductor fabrication tools

- High-temperature nylon inserts reducing acoustic emissions by 15dB

- RFID-embedded nuts enabling smart inventory tracking

Implementation in Heavy Machinery and Infrastructure

A 2024 case study on wind turbine installations showed hex screw nut

s with PTFE coatings increased service intervals from 6 to 18 months. Bridge construction projects report 30% faster assembly times using pre-lubricated flange nuts.

Hex Screw Nut Innovations Driving Industrial Evolution

The global hex nut market is projected to reach $28.7 billion by 2029, with smart factories adopting AI-driven torque verification systems. Recent patents reveal laser-welded security features preventing counterfeiting in automotive supply chains.

(hex screw nut)

FAQS on hex screw nut

Q: What's the difference between a hex screw nut and a hex nut screw?

A: A hex screw nut is a threaded fastener with a hexagonal head designed to pair with bolts. A hex nut screw typically refers to a screw with a hexagonal drive head, not a standalone nut. The terminology varies by regional usage.

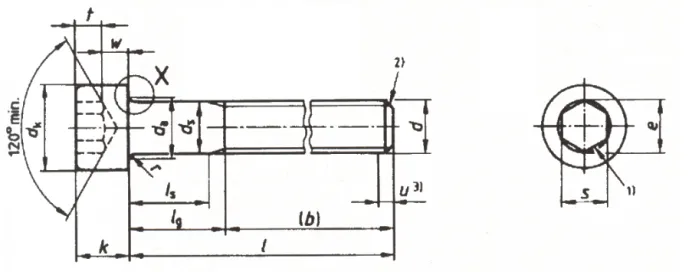

Q: What are standard dimensions for hex machine screw nuts?

A: Hex machine screw nut dimensions follow standards like ASME B18.2.2 or ISO 4032. Common sizes range from 0 (0.060") to 1" diameter. Dimensions include width across flats, thickness, and thread pitch.

Q: What tools are used to install hex screw nuts?

A: Hex screw nuts are installed using wrenches or sockets matching their across-flats measurement. Common tools include combination wrenches, adjustable wrenches, or power drivers with hex bits. Torque wrenches ensure proper tightening.

Q: How do I choose material for hex nuts in corrosive environments?

A: Opt for stainless steel (A2/A4), brass, or silicon bronze hex nuts. Coatings like zinc plating or hot-dip galvanizing add corrosion resistance. Match material to mating screw and environmental exposure.

Q: Are hex machine screw nut dimensions compatible across metric and imperial systems?

A: Metric and imperial hex nuts have incompatible thread pitches and diameters. A 1/4" nut (≈6.35mm) won't fit an M6 screw. Always verify thread standards (UNF, UNC, or metric) when mixing systems.

Post time: май . 07, 2025 16:08